Shoes are typically churned out as fast as possible with common standardizations in place, but everyone’s feet are different, so why are we settling for a generic shoe when we could be finding one that better fits our feet? Or in this case, making one that better fits our feet.

Shoes are typically churned out as fast as possible with common standardizations in place, but everyone’s feet are different, so why are we settling for a generic shoe when we could be finding one that better fits our feet? Or in this case, making one that better fits our feet.

That was the idea behind Dr. Casey Kerrigan’s decision to delve into the world of 3D printing. She explained that most shoes don’t contour to the exact specifications of each individual’s foot, and that can leave people susceptible to certain types of injuries.

“You can trace your bare foot on a piece of paper,” Kerrigan said. “Now trace the shoe that you’re wearing, and you’ll see that your foot actually falls outside of the lines of the shoe,” adding that inadequate support can lead to conditions like “metatarsalgia and Morton’s neuroma.”

To help people find a better fitting shoe, Dr. Kerrigan built a laboratory at the University of Virginia to study the way people moved. This allowed her to track certain biomarkers and understand the differing forces at play between individuals.

“We put markers down the body, and then there are these cameras around the room, and they pick up on where these markers are,” Kerrigan explained. “So we know exactly where the hip center is, the knee center, etc., and then they walk over these force plates, and from that we can assess how much impact there is at each of the joints.”

Creating The Shoe

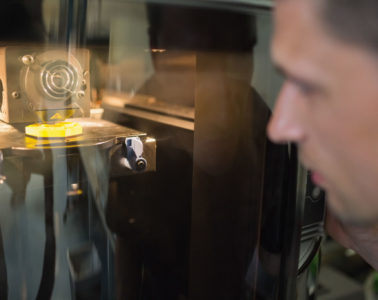

After looking at all the data, Dr. Kerrigan went to work designing a shoe that contours to the true shape of a person’s feet. That led her to form the brand OESH, which is a “reinvention” of the word shoe. Then she went ahead and began making the shoes with the assistance of many 3D printers.

The 3D printer allowed her to make shoes with a sole that were more springy than a standard foam insole. Not only does the elastic material provide cushioning, but it also provides spring, which is perfect for runners.

“The material had to be a very springy, elastic material. It can’t be foam, which is wonderful at cushioning but not good at providing spring, and we found that cushioning actually makes your joints work harder.”

The whole shoe is a work of art, and it’s good for the planet. Made of fully recyclable pieces, in theory, a worn down shoe could be shredded and remade back into a brand new shoe.

“And this is completely recyclable, so we can take this sole, shred it up, and put it right back into those printers and print a whole new pair of sandals. But it seems like a material that wouldn’t wear down all that easily. No, they won’t. We have one intern who hiked 4,000 miles on the Appalachian Trail in one pair.”

This is truly an innovative approach to take in order to solve a problem with women’s shoes – that fashionable options aren’t always good for your feet. Heels and narrow-toed options can overstress areas of your foot, but this well-designed, 100 percent green option is looking to fix all that. We’re excited to see if 3D printed shoes continue become more popular in the coming years.